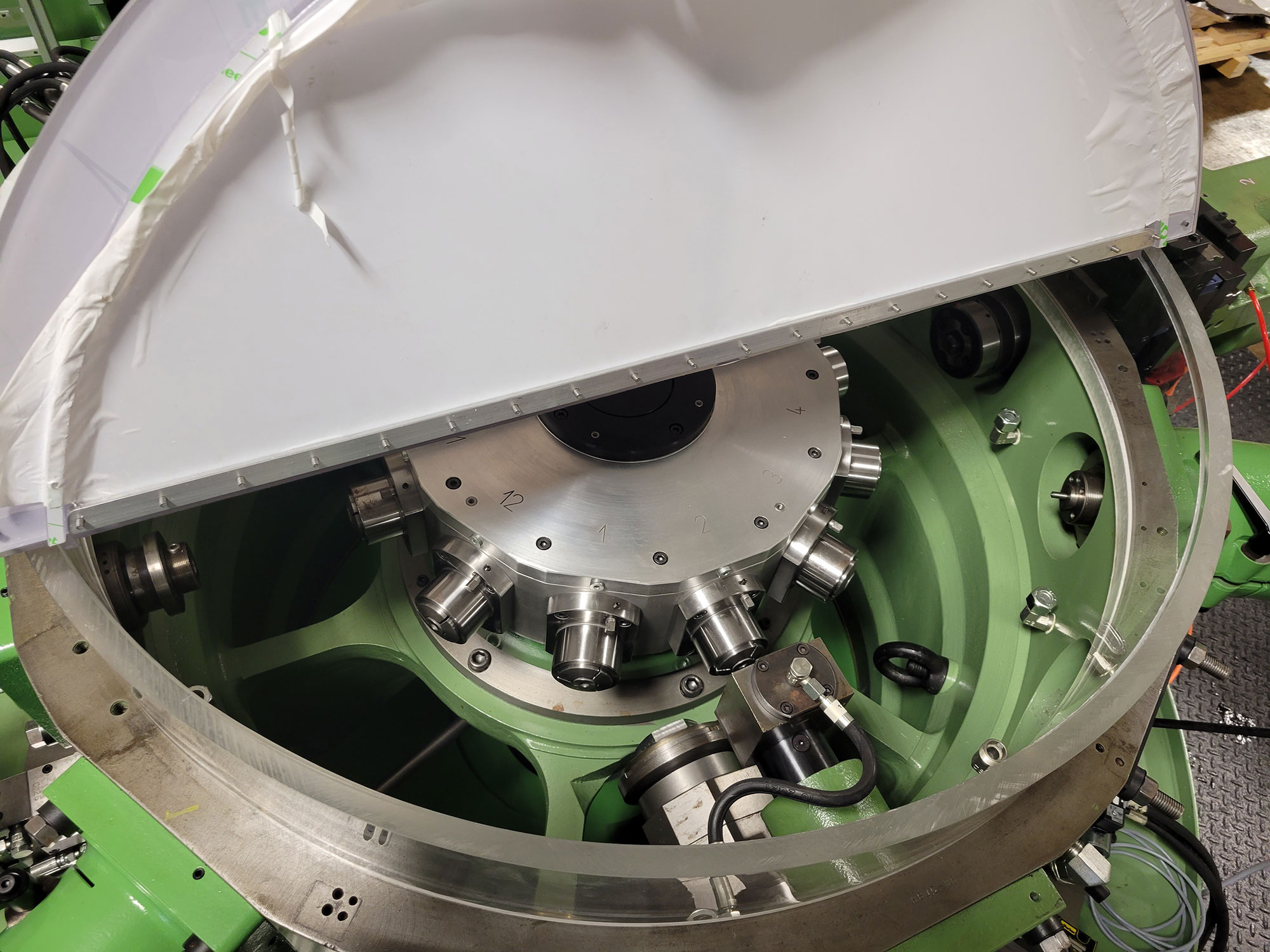

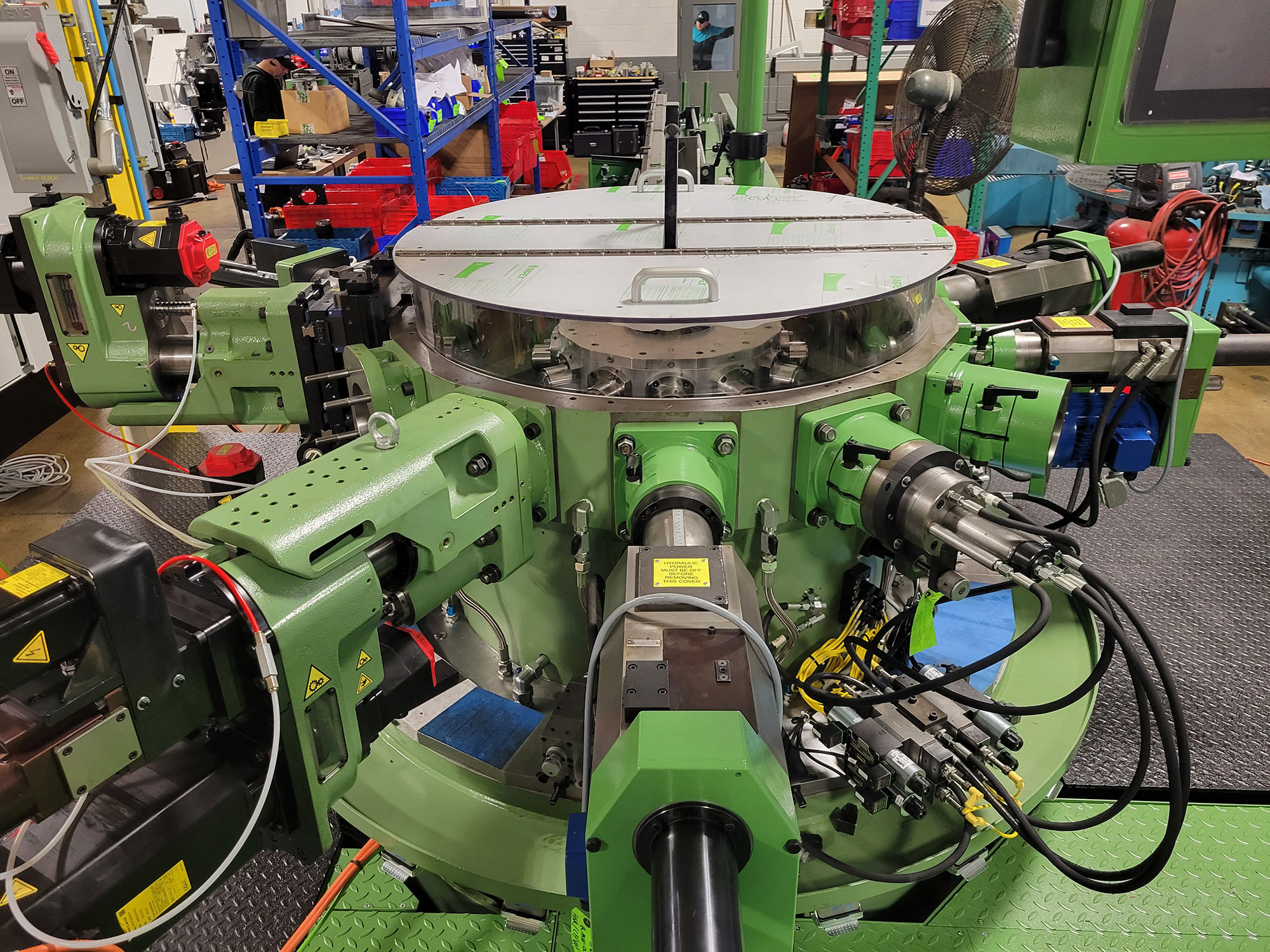

Hydromat Rotary Transfer Machining

Hydromat Rotary Transfer Machining

Our versatile, flexible Hydromat system with 16 stations and full CNC capabilities reduces the cycle time required for machining complex parts. Our hydromat is a fully rebuilt legacy machine with CNC capabilities. These rotary transfer machines are fitted with up to 16 sequential machining stations, including milling, drilling, turning, and burnishing, without moving the part from the machine. With our Hydromats, parts can be inverted to allow for rotary transfer machining operations on both ends during the production process.

Up to 1 5/8” bar capacity

12 and 16 spindle with automatic bar feeder

Customized for high accuracy and faster cycle times

Produces complex products